You do not begin to get full use from a lathe until you have a milling attachment. With it you can do slotting, keyway cutting, gear shaping, slitting and grooving. You can saw stock square or at angles, and spot holes in work with pinpoint accuracy.

A milling attachment costs a handful of folding money. But here is one you can make from two castings. They cost about a fourth what a finished attachment would. Machining them is fun, and may even teach you a few handy dodges. For instance, you mill parts of the castings to make the attachment you're going to mill with! When finished you have a husky, well designed lathe accessory that will not let you down.

By cleverly stacking cold-rolled flat stock together, T-slots and slide for this lathe milling attachment are made without costly machinery. In fact, only two tools, a drill press and lathe, are needed to make the attachment.

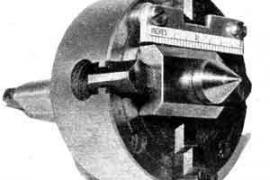

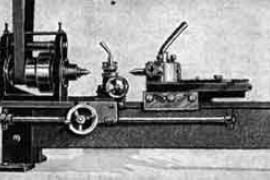

Shown mounted on the cross slide of a lathe the attachment features a swivel base and tilting slide which has T-slots for clamping the work securely in place. Although this attachment was made for a 7-in. Atlas lathe, the overall dimensions could be increased 25% for use with a 9 or 10-in lathe.